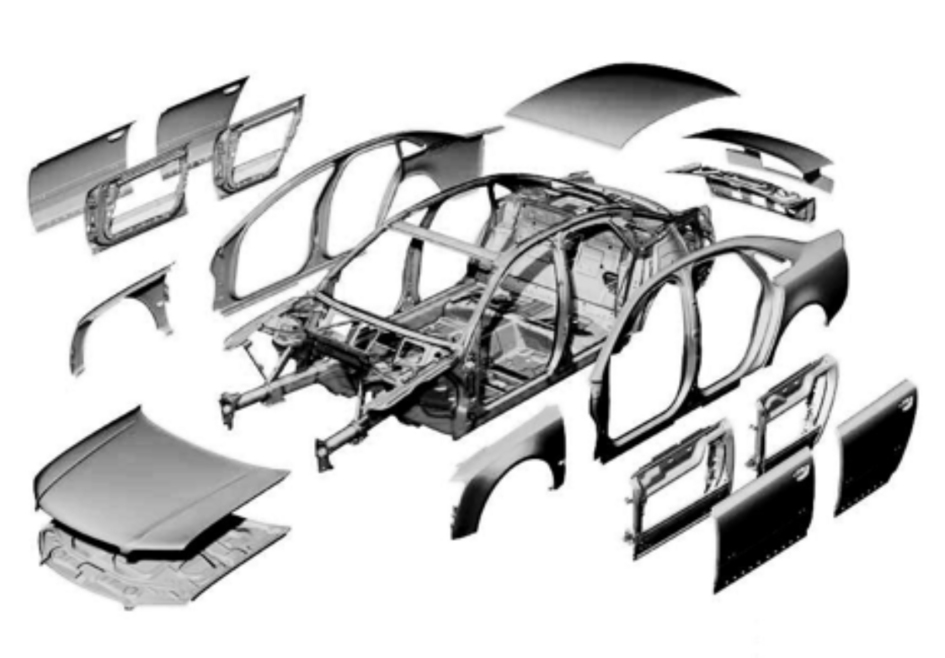

Werkzeugbau | Try-out | Neubau

Einarbeitung | Neubau

Experten für Oberflächenoptimierung von Außenhaut und Strukturteilen durch langjährige Erfahrung.

UNSERE LEISTUNGEN

- OBERFLÄCHENOPTIMIERUNG

- MASSLICHE FORM- UND SCHNITTKORREKTUREN

- EIGENSTÄNDIGE TEILANALYSEN

- WERKZEUGEINARBEITUNG / TRY- OUT

- AUF- UND NEUBAU

- INSTANDHALTUNG

- PRODUKTIONSBETREUUNG

- MÄNGELABARBEITUNG

- ABNAHMEN

Planung

Engineering

Das Zusammenspiel von Produkt, Produktion und Betriebsmitteln sehen wir als Voraussetzung für den Erfolg eines Projektes. Umfassendes Know How und ausreichende Kapazitäten, um den Herausforderungen gerecht zu werden, sind unsere Stärke.

Unser Angebot

- Monitoring / Follow-Up

(Terminüberwachung) - Änderungsmanagement

- Troubleshooting

- Projektbetreuung

- Prozessoptimierungen / Optimierung der Serienproduktion

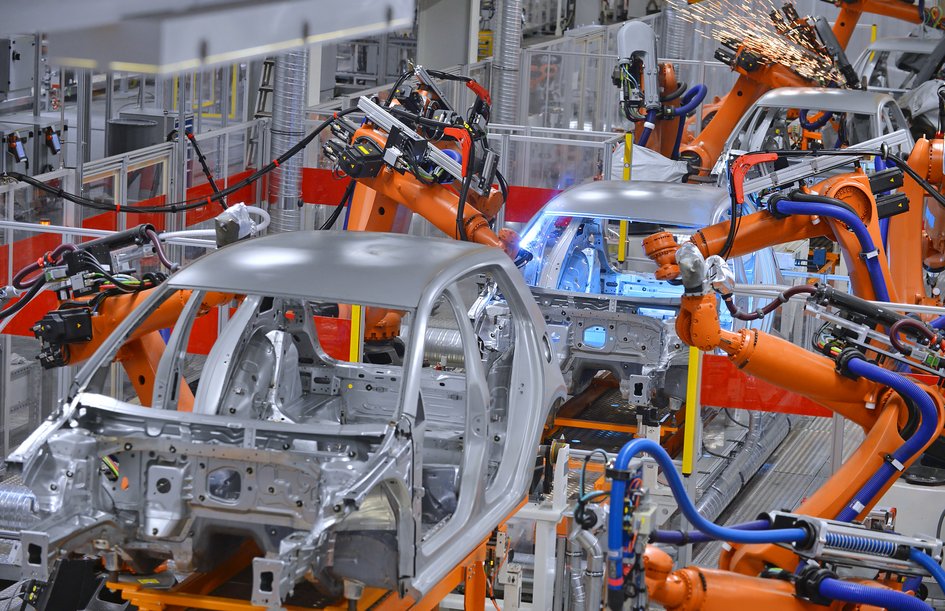

Rohbau

Fachliche Expertise in den verschiedenen Falzmethoden sowie im Aufbau des Roboter-/Maschinenparks.

Unsere Leistungen

- MASCHINENFALZEN

- ROLLFALZEN

- STELLMAßNAHMEN

- UNTERSTÜTZUNG BEIM AUFBAU DES ROBOTER-/MASCHINENPARKS

Personaldienstleistung

Wir unterstützen unsere Kunden bei der Beschaffung technischer Fachkräfte.

UNSERE LEISTUNGEN

- FACHKRÄFTEVERMITTLUNG IM BEREICH METALL/ELEKTRO

- ARBEITNEHMERÜBERLASSUNG

- DIENSTLEISTUNG IM WERKVERTRAG

- PERSONALVERMITTLUNG AUF PROVISIONSBASIS

Referenzen

ZSK Automotive GmbH

Kontakt

ZSK Automotive GmbH

Ettishofer Straße 8, D-88250

Weingarten

Zentrale

Tel. +49 (751) 56 81 97-0

Fax +49 (751) 56 81 97-75

E-Mail: zsk@zsk-group.com